Well Hello There Hivers!

The Start Of The Headache!

Now it wasn't a headache right from the start I have to be honest on that one!

It turned into a headache sometime later and the headache turned into a massive problem, although not as big as the problem was but it's right up the alley of "Screw Up City!"

When I started on this job I was actually quite keen for it, the first time in a long time where we do something other than working on a transmission!

Boy oh boy and it had to turn out the way it did!

Feel free to ask us if we know what we're doing!

Laughs we do just so by the way!

We Went The Extra Mile.

Not that it matters now though, see when I started taking photos when I got on the job with this one I never thought I would put down what I am going to put down!

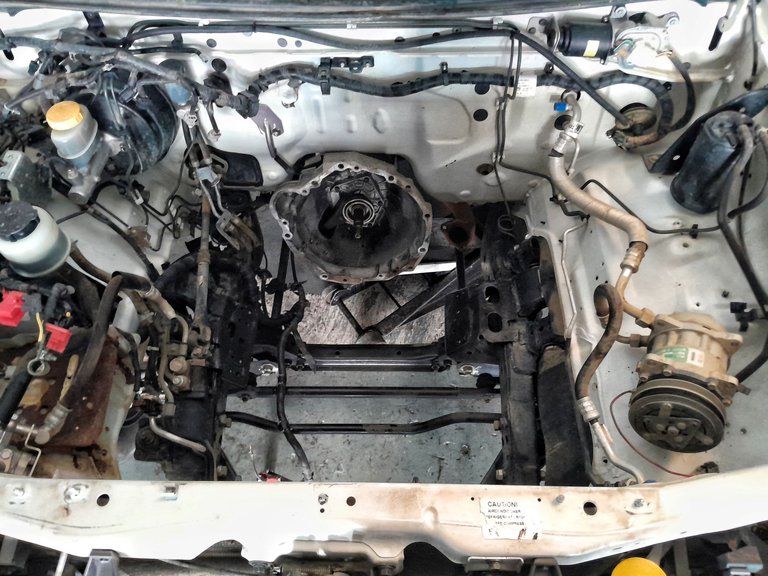

We really put some elbow grease into cleaning the entire bay for the newly rebuilt motor that we had to fit in!

A lot more care than what was needed went into this build, but as I have learned now that the more effort you put in the more problems you'll have!

That wont stop me from adding even more effort next time though!

The Spanner Throwing Isn't Far Off!

Everything seemed to go as smooth as it could ever go! Really!

We fitted the motor a lot faster than we should have and I was convinced this bad boy would be driving out of the shop on this day!

Destiny had other plans for us and Bossman!

Once the motor was fitted we had a bunch of small stuff to attend to, a water hose here and there that caused trouble but nothing out of the ordinary.

Small tedious stuff!

One Thing Led To The Other!

Now after all the tedious bits of work was behind us we had bigger problems now!

At-least the tedious part is done with hey!

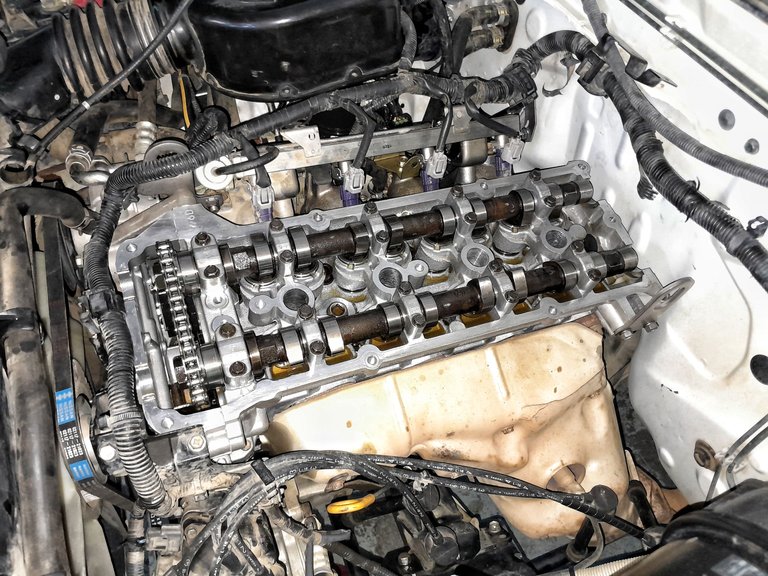

Now we're left with pulling the motor back out again!

WAIT A MINUTE!

WHAT?

Yeah you read that right! All the way through the tedious work and testing everything the motor ran completely fine!!! No problem at all, except for the problems we gave attention to!

After that it started getting a slight knocking sound and as we tried figuring out what it was it grew more consistent. At first we thought that a timing chain pulley might have gone loose but deep down inside of our guts we knew what was happening!

A Part Failure!

Now this came as a hard lesson to learn and one that I am glad I was able to learn!

The cause of the damage was because of a faulty oil pump we bought and it's no one's fault that the big end bearings got knocked up again. Well one might say it was the parts suppliers fault but how were they to know that the oil pump was faulty?

Always check and test new parts when you receive them! The guy from bearing works told us he has gotten so many of those faulty pumps and they are the worst on the old Nissan 1400 champ pickups!

Morale of the story? Always double check and make sure everything is indeed correct! If we tested the oil pressure before we even started sorting out everything this might have been a path for a different road!

Although there is no better way to learn than to cause a FUCKUP!

Dated 01/30/2024

Connecting the people of #HIVE across South Africa. #hive